Kevin’s Blog / A Cavitation Primer

SAGD short stories:

A Cavitation Primer

“SAGD short stories” is a blog series about SAGD and process operations.

Centrifugal pump cavitation can generate excessive noise, waste energy, and damage pump components.

Pump Cavitation is the spontaneous formation of bubbles (think of the bubbles as voids or cavities in the liquid) in

the relatively low-pressure zone near the impeller eye, which subsequently implode as the pressure increases toward the discharge.

The implosions are like small detonations, creating intense, focused micro-jets capable of breaking away small pieces of pump material.

While cavitation in a centrifugal pump is a serious concern for Process Operators, it is not confined to occurring inside a pump casing. In fact, a common example of cavitation is the stream of bubbles behind a fast turning boat propeller.

Let’s go a little deeper on cavitation.

Cavitation is a function of:

the relationship between a liquid’s pressure and boiling point

&

Bernoulli’s Principle

Daniel Bernoulli, in Hydrodynamica, 1738;

describes how the pressure of a fluid decreases

as the velocity of the fluid flow increases,

and vice versa

In regard to cavitation, a pump impeller and a boat propeller have a lot in common. Both rotate in liquid and drive localized pressure changes. And both can create the conditions required for cavitation.

As a propeller turns, the blade creates a high-pressure zone behind the prop to drive the boat forward, but also creates a low-pressure zone in front of the prop.

If the prop turns fast enough, the pressure drop can reduce the water’s boiling point to below the water’s actual temperature, causing some water to literally boil.

Vapour bubbles (think steam) spontaneously form in the liquid approaching the low-pressure eye. The bubbles are carried with the moving water into the high-pressure zone, where the water velocity slows and the pressure spikes. These conditions collapse the bubbles violently, with each bubble collapse being a tiny detonation.

How the damage happens

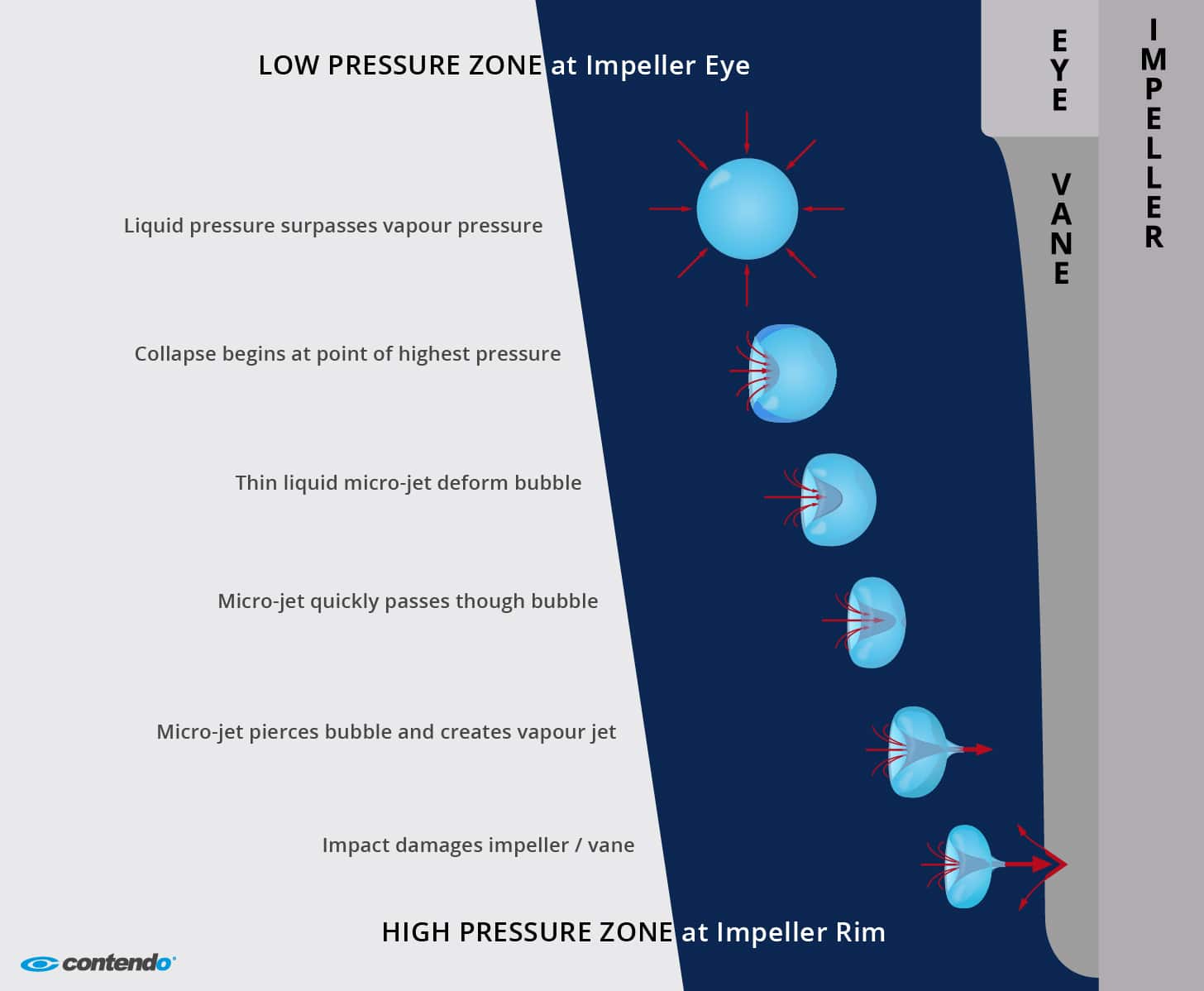

Cavitation causes damage to the pump because of the way the bubbles collapse.

It is important to understand the increasing pressure is not applied equally across the entire surface of the bubble. Because of this, the collapse begins at the point on the bubble where the most pressure is forcing on it, like a finger pushing into a balloon.

This collapse creates a liquid micro-jet that crosses the void of the bubble at high velocity, turning the void into itself. The velocity of the liquid jet, when it pierces the opposite side of the bubble, draws some of the bubble vapour into the liquid, creating a destructive vapour jet.

It is the intense impact forces of these high velocity vapour jets that crack or chip pump parts.

Cavitation events chipping away at a prop or impeller is called cavitation erosion, and can leave parts looking rough, with holes eaten through, or with blades and/or vanes almost worn away.

FYI. An additional hazard of cavitation noise is specific to ships. In cases where naval actions are happening, cavitation can be heard for a long distance by military listening equipment, and can be used to target ships.

Pump Cavitation

The pressure changes forced on a liquid passing through a properly operating centrifugal pump can also induce cavitation. In regard to operating a pump, remember that if the liquid temperature is already near its boiling point, it will take less pressure drop to induce cavitation.

Suction cavitation

can occur if the pump is starved. Bubbles will form at the impeller eye, and then implode on the face of the impeller.

This can happen if the pump is operating with:

- Low suction pressure (low NPSH / high vacuum)

- Excessive flow rate

- Insufficient suction flow

Poor design could result in suction cavitation if the pump operates too far to the right on the pump curve.

If you suspect suction cavitation:

- Confirm the discharge flow rate is not excessive

- Check for anything impeding flow into the pump, such as:

- A very low feed tank level

- A partially closed feed valve

- Upstream strainer / filter plugging

Discharge cavitation

can occur if the discharge pressure is so high it’s hard to get the liquid out of the pump. The velocity of liquid circulating inside the pump can create low pressure near the casing wall where bubbles form. The bubbles then implode on the casing wall and impeller tips.

This can happen if the pump is operating with:

- Excessive discharge pressure

Poor design could result in discharge cavitation if the pump operates too far to the left on the pump curve.

If you suspect discharge cavitation:

- Check for anything impeding flow out of the pump, such as:

- A partially closed discharge valve

- A closed or failed minimum flow recirculation valve

- Downstream strainer / filter plugging

To find out more about how to operate in the Canadian Oil Sands,

you can view Contendo’s SAGD Oil Sands Online Courses.

Kevin Fox is a senior technical writer at Contendo.

He is a power engineer who has written process education programs for industrial clients since 2009.

This Post Has One Comment

Leave a Reply

You must be logged in to post a comment.

Pingback: A Cavitation Primer - Kevin Fox Freelance Writing Kevin Fox Freelance Writing