Kevin’s Blog / What a Relief

[vc_row][vc_column][vc_column_text]

Kevin’s Blog / SAGD short stories:

What a Relief!

“SAGD short stories” is a blog series concerning SAGD operations.

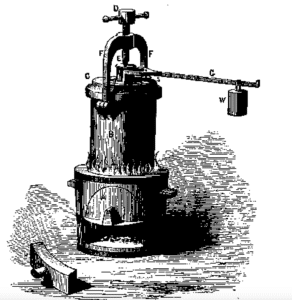

While modern instrumentation provides a multitude of engineering options to plant designers, there is no better example of simplicity in design than a mechanical pressure relief device.

From the first time a lid was fitted to a cooking pot, we have taken advantage of the increased temperatures attainable in a “pressure vessel”. In fact, it was around 1680 when the inventor Denis Papin fit the first basic pressure relief device to a pressure cooker.

A pressure relief device can be installed to protect against over-pressure damage in piping systems, on vessels, or as an integral part of some equipment, such as compressors. There are also vacuum relief devices to protect containers such as pressure vessels and closed tanks from being crushed by atmospheric pressure due to excessive vacuum developing inside the container.

Relief devices include:

-

Pressure Safety Valves (PSV)

-

Pressure Relief Valves (PRV)

-

Vacuum Relief Valves (VRV)

-

Pressure and Vacuum Relief Valves (PVRV)

-

Burst / Rupture Disks

Specific devices are used on systems expected to handle liquids only, gases only, or mixes of each.

For steam systems, it is the relationship between mass, temperature, and container volume that affects pressure. If a fixed amount of water (mass) is boiled (temperature) in a fixed container (volume), its pressure is increased. In this case, some heat energy is converted to pressure.

For liquid handling systems using pumps, it is the relationship between flow, the pump, and the piping volume that affects pressure. If the piping volume and the liquid volume can’t change, any change in flow rate will change the pressure. This is true whether the change is in pump function or flow restriction. In this case, some of the energy used by the pump is converted to pressure.

Gas handling systems using compressors, such as instrument air systems, can affect pressure in two ways. First, the compressor reduces the volume of a fixed mass of gas, which creates the compressor’s discharge pressure. In this case, some of the energy used by the compressor is converted to pressure. Second, restrictions applied to the pressurized discharge stream can determine the pressure available to specific downstream users.

In each of these cases, there is the potential to exceed the pressure necessary for the process or even the maximum allowable pressure of the design. If no steam is allowed out of a boiler, or downstream upsets cause users to close off liquid or gas supply valves, operating pressures will quickly increase. If the changes occur too fast for the Process Control System to respond, it falls to mechanical relief devices to save the day.

The relief device immediately responds to excessive pressure by opening and safely relieving a portion of the pressurized stream to an appropriate location. In the case of a steam relief event, this can be to an outside location away from other activities or to a receiver vessel or tank. In order to contain more hazardous gas or liquid relief streams, this is often through dedicated piping back to the source vessel being drawn from, or to a dedicated relief vessel (such as a flare knock out drum).

The difference to the operator between immediate relief or none at all could be a small upset versus a destructive event that could shut down a process for major repairs.

And knowing your system has a tested and confirmed pressure relief capability is one less thing to worry about. What a relief!

To find out more about SAGD and operating in the Canadian Oil Sands,

you can check outContendo’s SAGD Oil Sands Online Courses.

Kevin Fox is a senior technical writer at Contendo.

He is a power engineer who has written process education programs for industrial clients since 2009.

To Learn More

At Contendo, we have been providing in-depth online operator training to the Oil Sands and SAGD industry for the better part of a decade. If you want to learn more about SAGD or process operations, stay tuned for more posts like this, or contact us to hear more about our Online WHMIS Training Course.

Was this article helpful? We’d love to keep in touch with you. Click here to sign up for our online newsletter.