Kevin’s Blog / FREE GAS?

SAGD short stories:

FREE GAS?

“SAGD short stories” is a blog series about SAGD and process operations.

It’s common in manufacturing industries to find productive uses for waste streams wherever possible. Since SAGD operations require lots of steam (commonly generated from natural gas-fired boilers) any process generating hydrocarbon vapours as a “waste” stream can be set up to transfer the usable gases to the facility fuel gas system.

While not providing completely FREE GAS, the capability to recover hydrocarbon gas for use as boiler fuel is a considerable economic advantage. In fact, a significant portion of the facility fuel gas can be recovered in conjunction with ongoing bitumen recovery operations; that is, without any additional energy input.

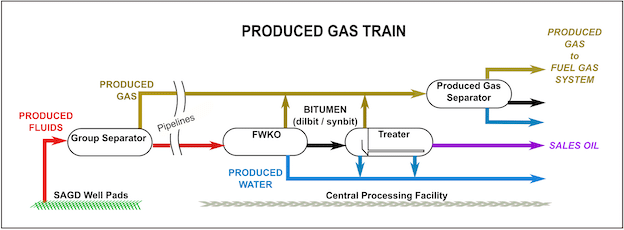

SAGD wells produce an emulsion of hot, high-pressure hydrocarbon liquids and gases, water, and steam to the surface. At each Well Pad, produced fluids are combined and passed through a Group Separator, which is a 2-phase gravity separator.

The fluids are passed through the separator quickly so water and hydrocarbons don’t separate. Reductions in temperature and pressure encourage gases to break out and gather in the space above the liquids. These hydrocarbon gases are called Produced Gas (PG).

Note: Despite the reduction in pressure, the produced gas and produced fluid streams exiting the well pad separator vessels are still under very high pressure.

The gases and liquids are sent to the Central Processing Facility (CPF) in separate pipelines.

The Produced Gas is processed at the CPF to fuel the steam generators.

This reduces the amount of natural gas that has to be purchased.

The produced gas reaching the CPF is a hot, wet vapour stream. Cooling is unavoidable during transport in the pipeline, and this condenses some water and hydrocarbon liquids (condensates). This makes condensate drainage and recovery from the pipelines very important.

At the CPF, the produced gas will be passed through a gravity separator. Individual designs vary greatly, and this may or may not be the first vessel in the process train.

Some designs have inlet heat exchangers before the gravity separator. This usually serves two purposes; for example, cooling the produced gas by pre-heating boiler feed water. An exchanger here can be called a PG Condenser or PG Cooler. It will definitely have a closed drain system for condensate recovery, as the cooling effect will generate liquids.

A typical Produced Gas Separator (3-phase gravity separator) receives wet produced gas from the field Group Separators as well as from gravity separators in the bitumen processing trains. The design and operation of the vessel knocks liquids out of the vapour stream and generates dry produced gas, hydrocarbon condensates, and produced water.

The hydrocarbon condensate is drawn from the liquid surface and sent to the bitumen processing trains to recover the value in the hydrocarbons.

The water condensate is drawn from the bottom of the vessel and sent to the produced water processing trains to be recycled to boiler feed water.

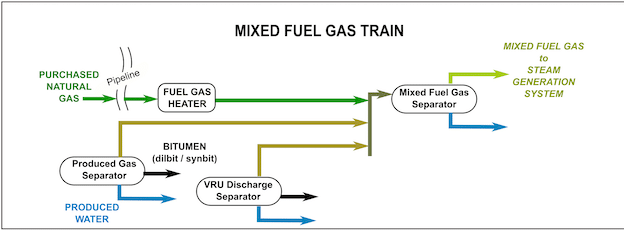

The dry produced gas is sent to a Mixed Fuel Gas Separator where it is blended with purchased natural gas to create a “mixed fuel’ for the steam boilers.

The purchased gas is delivered via pipeline. It is pre-heated before being blended with the produced gas, which is still hot, in order to avoid forming gas hydrates at any pressure let down in the fuel gas control train (gas hydrates are like ice and can block piping).

Other sources feeding produced gas to a mixed fuel system can include Free Water Knock Out and Treater separation vessels, and Vapour Recovery Units.

The combined gas stream is sent through the mixed fuel gas separator to remove all liquids (which are mostly water) from the fuel gas feeding the steam generator burners.

It’s important to remove water and other liquids from the fuel gas because:

-

Carbon dioxide and water can form corrosive carbonic acid in piping

-

Liquids cause flame instability and incomplete combustion at the burners

-

Liquids can enter and block control system sensing lines

The dry, pre-heated mixed fuel gas is now ready to be fed into the steam generation fuel system without concern for

dirt, liquid, or hydrate formations blocking or affecting gas flow or control sensing lines.

By utilizing produced gas as fuel, we can significantly reduce the total cost of the SAGD operation.

To find out more about how Produced Gas is processed and utilized in SAGD,

you can view various chapters of Contendo’s SAGD Oil Sands Online – Well Pads and Bitumen Processing Courses.

Well Pads Course chapters include: Group Separator and Test Separator.

Bitumen Processing Course chapters include: Emulsions, Separation, Bitumen Inlet, Treater, Produced Gas Condensers, Produced Gas Separator, VRU Compressor and Discharge Separator, Main Fuel Gas, and Mixed Fuel Gas Separator.

Kevin Fox is a senior technical writer at Contendo.

He is a power engineer who has written process education programs for industrial clients since 2009.