Kevin’s Blog / A “Look” Inside

Kevin’s Blog / SAGD short stories:

A “Look” Inside

“SAGD short stories” is a blog series about SAGD and process operations.

When planning a Confined Space Entry one of the most important steps is to confirm the actual internal conditions. This is particularly true in regards to the quality and composition of the confined atmosphere.

Before anyone can go into a Confined Space, the team needs to take a “look” inside.

Canadian regulations require all Confined Spaces to be identified with supporting documents, like Hazard Assessments; and pre-approved Preparation and Entry Procedures. A major piece of the preparation is finding out what hazards exist inside the space without putting anyone at risk. Remote atmospheric testing is a reliable way to get this done.

The atmospheric levels need to be checked for oxygen, flammable or explosive gases or vapours, and toxic gases or vapours; normally in this order. Other potential atmospheric hazards include biological contaminants, like mould or bacteria; and irritants, such as fumes, smoke, dusts, and mists.

The best case scenario would be testing a Confined Space equipped with permanently mounted gas monitoring and reporting capability that has been designed to be entered occasionally. In this case, test results can be recorded from the monitoring panel. Unfortunately, cost makes this the exception rather than the rule.

Tools

It’s more common to perform the testing manually with handheld gas detection and measuring meters. Some meters test for only one substance, while others can test for multiple substances.

Samples are drawn to the meter through tubing, which is inserted into the space through an opening, while the test person remains safely outside.

Test Pattern

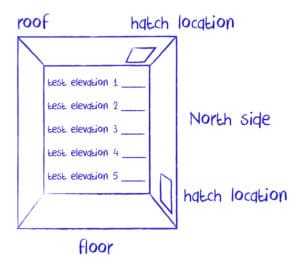

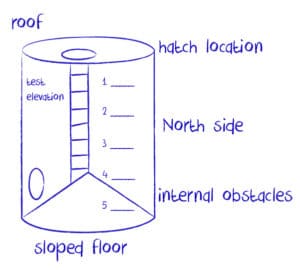

Test samples must be drawn from a number of internal locations, including at multiple heights. The results are then recorded and used to develop a profile of the contents.

Good practices for testing include:

-

Allowing only trained and qualified personnel to use the test equipment.

-

Double checking that the correct type of meter is used for each test.

-

Confirming that the meter has been properly calibrated and tested.

-

Avoiding the potential for local air contamination when establishing a zero reference for the meter. (This requires “clean” air).

-

Testing for oxygen first, since other tests may require the presence of oxygen to be accurate.

-

Testing all areas of the space. (Taking into account gas densities and hard to ventilate places).

-

Continuing to periodically repeat the tests during the entry operation.

-

Clearly recording all results. (This can include a hand-drawn diagram specifying the exact internal location of each test).

-

(and the big one!)Interpreting the results correctly.

Interpretation

The test results have to be assessed against all potential or known variables. The specific confined space Hazard Assessment should list all substances to be tested for. Workers in the area should always be asked if any unusual work is being done in case new hazards have been created since the Assessment was developed.

For example:

A utility vacuum truck, being used in vessel cleaning,

could add a carbon monoxide hazard

due to exhaust gases accumulating in the testing area.

Unless this was considered in the Hazard Assessment,

CO testing would have to be added to the procedure.

While Confined Space Entry education and training is mandatory, and most procedures follow established guidelines and regulations, the ability of the entry team to fully assess all real and potential hazards adds another level of safety consciousness to one of the most hazardous jobs we do.

Always use all of your knowledge and experience when planning and performing the tests.

Poorly planned and completed testing, or testing without understanding and accounting for

the actual local conditions, can result in incorrect readings.

Decisions made based on incorrect interpretation of test results put personnel and/or equipment at risk.

Any mistake in atmospheric testing can cost a life so always BE SURE BEFORE ENTRY IS ALLOWED!

To find out more about SAGD and operating in the Canadian Oil Sands,

you can check out Contendo’s SAGD Oil Sands Online Courses.

Kevin Fox is a senior technical writer at Contendo.

He is a power engineer who has written process education programs for industrial clients since 2009.

To Learn More

At Contendo, we have been providing in-depth online operator training to the Oil Sands and SAGD industry for the better part of a decade; but we also have a suite of safety related products. If you want to learn more about Confined Spaces, stay tuned for more posts like this, or contact us to hear more about our Confined Space Awareness Course.

Was this article helpful? We’d love to keep in touch with you. Click here to sign up for our online newsletter.