Procedures & Small Business: Part 4

Is an ISO Compliant Program the Answer?

While a small business with limited resources may never work toward an ISO certification, adopting ISO-style work procedures can be one of the most impactful management decisions a small business manager can make.

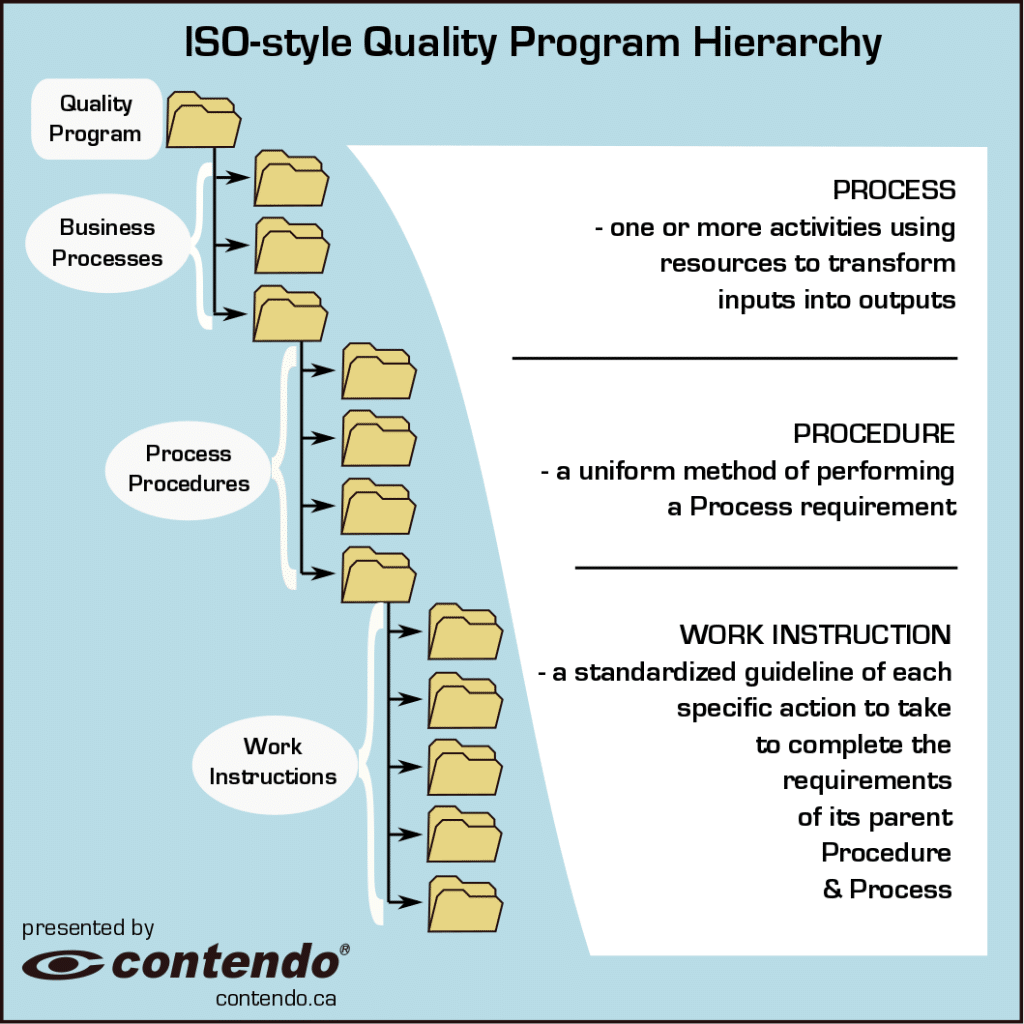

The word procedure is very loosely used in most workplaces not ISO certified, and this needs to be clarified to understand the ISO idea. Since ISO is all about standards, its quality management standard format divides what are generally called procedures into 3 distinct levels of content detail: Processes, Procedures and Instructions.

Here are 3 levels of an ISO quality program document hierarchy that can be utilized by a small business.

1. Process Document

Process – one or more activities using resources to transform inputs into outputs.

Examples: Operations Processes; Planning Processes; HR Management Processes

A Process Document is a high level summary of what a process is and why the process is necessary.

2. Procedure Document

Procedure – a uniform method of performing a process requirement.

Examples: Operating Procedures, Maintenance Procedures, Admin Procedures

A Procedure Document (or Procedure) is a statement of how to meet the process requirements, but without including execution details. It will include things like the responsibilities of involved personnel (usually by Job/Position), safety information and hazard warnings, as well as methods to use in performing the procedure and measuring results.

3. Work/Task Instruction Document

Work Instruction – a standardized guideline of each specific action to take to complete the requirements of its parent Procedure and Process.

Examples: Lab Analysis Instructions; Equipment Start-up & Operating Instructions; Equipment Maintenance Instructions

A Work Instruction or Detailed Task Document is the actual detailed step-by-step explanation of how to execute all or part of a process.

Many small businesses consider Work Instructions to be Procedures, but ISO says they are different. Let’s look at a Trucking company as an example of an ISO-style document hierarchy.

A company will have

one or more operational Processes. Each Process is concerned with a specific

business operation.

Our example Processes are: Dump Truck Ops; Tractor/Trailer Ops

Each Procedure is

concerned with one aspect of the parent Process.

Our example Procedures include: Driver Reporting; Maintenance; License/Admin

Each Detailed Task or Work Instruction is in turn only concerned with one aspect of the parent Procedure. In our example, the Driver Reporting Procedure includes Work Instructions for completion of the Driver Daily Inspection, the Driver Log Report, and the Driver Incident/Accident Report.

Example of a Single Process

– Additional Procedures & Work Instructions

Trucking Company

– ISO-style Process: Procedure: Work Instruction

Process: Dump Truck Operations

Procedure: Driver Reporting

Work Instructions:

Driver Daily InspectionDriver Incident/Accident Report

Driver Log Report

Process: Dump Truck Operations

Procedure: Maintenance Reporting

Work Instructions:

Vehicle Annual Inspection

Vehicle Annual Service

Vehicle Monthly Inspection

Vehicle Monthly ServiceVehicle Provincial Safety Cert Pre-Inspection

Vehicle Weekly InspectionVehicle Weekly Service

Process: Dump Truck Operations

Procedure: License/Administration

Work Instructions:

Vehicle License & Insurance Storage/Display

Vehicle Roadside Emergency Equipment Inspection

The ISO documentation program is a proven performer and adopting it for a small business could show a commitment to quality to employees and clients. It could even speed up training new employees as anyone coming in from an ISO compliant or ISO certified workplace would be quick to grasp and utilize the familiar program.

The hurdle for many small and medium size businesses is simply getting started on the path to high-level procedure writing and adoption. If you think ISO-style procedures can help you in your job, please share this blog with your manager.

Kevin Fox is a technical writer at Contendo. He is a power engineer with a background in process operations, steel fabrication and military.