Kevin’s Blog/ The SAGD Life Cycle

Kevin’s Blog / SAGD short stories:

The SAGD Life Cycle

“SAGD short stories” is a blog series about SAGD and process operations.

The Steam Assisted Gravity Drainage thermal heavy oil production method

introduces heat into a target reservoir to mobilize and recover viscous bitumen.

At every SAGD Well Pad,

production returns eventually drop off until continuing is not worth the cost,

marking the end of the pad’s SAGD life cycle.

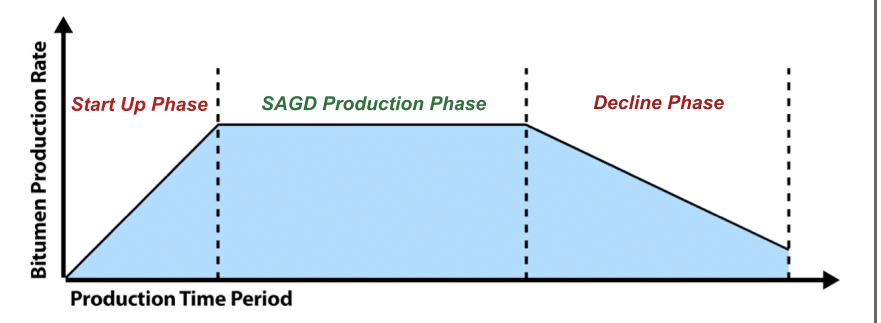

The “SAGD Life Cycle” refers to 3 distinct operating phases:

The Start Up Phase

The SAGD Production Phase

and

The Decline Phase

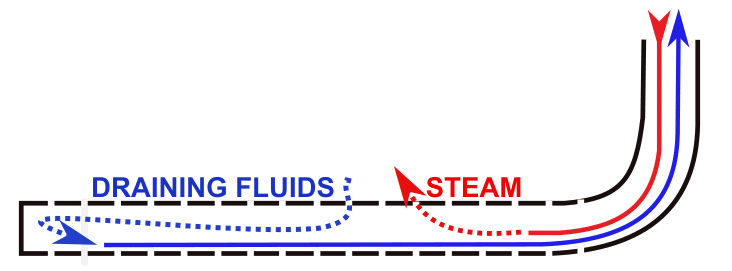

SAGD wells are drilled horizontally at the reservoir depth.

A Producer Well is placed near the bottom of the reservoir.

A matching steam Injector Well is set a few meters above and parallel

to the Producer to make one Well Pair.

Most discussions of a SAGD Well Pair call the wells

“Injector” and “Producer”, but for parts of this discussion

I will use “upper” and “lower” to name the wells.

The purpose of the SAGD Start Up Phase is to establish communication between the wells.

To do this, high-pressure steam in excess of 200ºC is used to heat the sand immediately around each horizontal well.

A SagD Footnote!

SAGD wells have a “heel” at the bend from vertical to horizontal,

and a “toe” at the very end.

The horizontal part of the well is a slotted pipe that allows steam out and fluids in. Separate tubing (piping) inside the casing runs to the toe and the heel for steam injection or fluid production.

This allows steam injection into the reservoir through the toe and

simultaneous fluid production into the heel of every well, or vice versa.

Injecting steam through the toe tubing will heat up and drain fluids from the immediate area.

Maintaining a pressure differential between the toe and the heel tubing will move drained fluids into the heel tubing.

Initially, steam condenses rapidly as the reservoir acts like a heat sink, and very little bitumen is returned with the produced fluids.

Once the entire length of well is heated, a localized steam chamber begins to form and expand upward.

The upper well steam chamber will eventually be stopped by cap rock.

I’d like to point out that the “steam chamber” is where bitumen has

already been recovered from the sand. It is a “void in the bitumen”.

The actual draining of mobilized bitumen only occurs at the

periphery of the expanding high temperature steam chamber.

When a lower steam chamber begins to interact with an upper steam chamber, we can say communication has begun.

The Start Up Phase can take months to establish communication between the wells.

The time it takes is mainly dependent on the:

-

Pressure of the injected steam

-

Temperature of the injected steam

-

Reservoir quality

Changes in downhole pressure, temperature, and flow rates of steam and produced fluids,

indicate when reservoir fluid mobility and communication between the wells has been established.

At this point, operation of the upper and lower wells as a SAGD Well Pair can be started.

This requires steam injection only through the upper well and production of fluids only from the lower well.

HP steam is supplied to the upper well toe and heel tubing. The steam pressure in the slotted pipe

forces steam out and discourages drainage into the pipe.

The “upper” is now the “Injector”.

The lower well toe and heel are set up to flow fluids to the surface. Setting the production tubing pressures

below the steam injection pressure encourages drainage into the slotted pipe and tubing.

The “lower” is now the “Producer”.

The Well Pair is now operating in the SAGD Production Phase.

The Production Phase can continue for as many years as necessary to recover the maximum amount of oil available to the Well Pair.

During the Production Phase, individual steam chambers eventually heat the whole target zone.

The cap rock defines the upper boundary of the reservoir,

maintains the pressure built up by the steam injection, and prevents breakthrough to the surface.

Over time, the reservoir heating efficiency drops off as

more of the available heat is transferred to the cap rock and overburden and less to bitumen in the sand.

This leads to a decline in oil production, and means more steam is needed to maintain maximum oil production.

The SAGD Decline Phase generally begins after approximately half of the recoverable bitumen has been extracted.

This is when production begins to decline while the amount of steam required to produce each barrel of oil begins to increase steadily.

As the steam chamber grows, production from the well pair eventually becomes uneconomical

due to the large quantity of steam required to produce the remaining bitumen,

and production from the wells is discontinued.

To find out more about the operating life cycle of SAGD wells,

you can view the Well Life Cycle chapter of Contendo’s SAGD Oil Sands Online – Well Pads Course.

Kevin Fox is a senior technical writer at Contendo.

He is a power engineer who has written process education programs for industrial clients since 2009.

To Learn More

At Contendo, we have been providing in-depth online operator training to the Oil Sands and SAGD industry for the better part of a decade. If you want to learn more about this complex but highly efficient extraction method, stay tuned for more posts like this or contact us to hear more about our SAGD Oil Sands Online Training Course.

Was this article helpful? We’d love to keep in touch with you. Click here to sign up for our online newsletter.